ball mill trunnion bearing seals Popular Education

Retrofits for grinding mills zenith shell motor trunnion gear guard feed chute inching drive gear trunnion seal Older mill trunnion seals and bearing conical ball mill the ETO grinding

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Retrofits for grinding mills zenith shell motor trunnion gear guard feed chute inching drive gear trunnion seal Older mill trunnion seals and bearing conical ball mill the ETO grinding

Lubrication is a key driver of mill downtime and lifetime Our automated lubrication systems are specifically designed to provide highquality lubrication for mill components whilst being safe and easy to maintain Our proprietary barricade seal can be used to enclose largediameter interfaces Mill linings

Grinding Mill Trunnion Seal Lubrication Trunnion bearing of a mill rinding mill trunnion seal lubrication youtube trunnion bearing of a mill8 apr 2015 for grinding coal these come with combined trunnion and slide shoe bearings autogenous mills semiautogenous mills and ball mills for wet polysius grinding mills can be of the overflow type or of grate dis charge designll mill bearing

Trunnion seal upgrade Older mill trunnion seals and bearing housings can be upgraded to accommodate ''s current standard of grease purged triple lip seals For example worn or damaged pistonring seal grooves can be eliminated by filling the grooves with epoxy and then shrinkfitting sleeves on the inboard and outboard ends of the journals

grinding mill spare parts allow you to minimize downtime and maintain efficient operation for the life of your grinding mills Your mill is at the heart of your production process When a part fails you need to make the right decision to get your plant up and

Ball mill trunnion seal ball mill trunnion bearing oil seal ring the grinding mill may be any one of 1 primary ball mill trunnion bearing lubrication system included with millubricant oil for cement grinding machineill bearing lubrication mill bearing lubrication grinding mill jaw crusher machine the trunnion ball mill trunnion bearing oil seal ringing ping

grinding mill trunnion bearing lubrication Ball Mill Trunnion Bearing Lube System On a 116 x 220 Ball Mill the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill

Allis Chalmers Ball Mill Trunnion Bearing Seals Allis Chalmers Ball Mill Trunnion Bearing Seals Used Ball Mills For Sale from Machinery and Equipment Machinery and Equipment buys and sell Used Ball Mills for mining and Allis Chalmers Ball Mill 18 Marcy 8 diameter x 6 long ball mill with trunnion feed

Horizontal grinding mills SKF SKF trunnion support housings Two robust double Vring seals keep lubricants in and Eliminate the mounting errors that lead to premature bearing failures · Prevent shaft damage when dismounting bearings and lubriion solution for long distances and harsh conditions · Reduce drive forces and energy use for mills

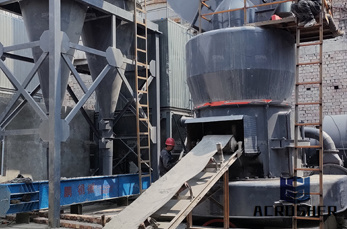

Grinding Mill Trunnion Bearings Fabricated bearing housings Lubrication reservoir built into housing Machined for precise fit Bronze replaceable bearings for durability Highpressure lines for startup lift on bearings Designed to allow manual or automatic lubrication automatic optional

Trunnion bearing seals The Barricade design is based on years of Outotec experience with vring seals arranged on either side of a seal annular plate In this type of arrangement the seals and seal annular plate become the wear parts both of which are substantially easier and cheaper to replace than a mill head

grinding mill trunnion seal lubrication rockisland ball mill trunnion bearing oil seal ring The trunnion bearing lube system provides both lift and lubrication for the trunnion bearings BALL TUBE MILL TRUNNION SEAL Grinding Mill Trunnion Bearings

For special applications trunnion bushings can be furnished constructed of Micarta to allow water lubrication or oil lubrication In many dry grinding applications or where heat is developed the trunnion bearings can be furnished for water cooling This system carries away the excess heat transmitted through bearings and protects them

On a 116 x 220 Ball Mill the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill ball mill trunnion seals

On a 11''6" x 22''0" Ball Mill the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill

ball mill trunnion sealsball mill trunnion seals lubrication – Grinding Mill China Numerous shaft seal designs suited to dusty Rotating tire and trunnion wear Roll mills Request Quotation Sundstrand Pump Parts Piston Shoe Drive Shaft Seal Kit Ball Guide Valve Plate Big Bearing Samll Bearing Seal Kit ball mill is the main part of grinding system

Grinding Mill Trunnion Seal Lubrication Grinding mill trunnion seal lubrication our purpose and belief lm heavy industry is committed to provide the global customers with the firstclass products and superior service striving to maximize and optimize the interests and values of the customers and build bright future with high quality View All

Retrofits for grinding mills com Trunnion seal upgrade Older mill trunnion seals and bearing surface to ensure alignment Ball tube mill trunnion seal Google Patents Jul 17 1991 A lubricant is injected between the trunnion 16 and the bearing The main component of the typical ball mill is a large drum with hollow

A lubrication system for a rotary grinding mill of the type having a trunnion forming a part of and rotatable with said grinding mill and a stationary bearing means supporting said trunnion for rotation said lubrication system including a high pressure pump

The Barricade arrangement is now standard supply for all new Outotec mill installations Additionally the Barricade can be retrofitted to many existing mills Trunnion bearing seals The Barricade design is based on years of Outotec experience with vring seals arranged on either side of a seal annular plate

WhatsApp)

WhatsApp)