How Cement Is Made

How cement is made and history of Portland Cement

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

How cement is made and history of Portland Cement

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

Dry, semidry, semiwet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

Heavyduty performance 2 Ideal for both prehomogenisation and buffer storage of raw materials, FL stacker and reclaimer systems have an impressive track record ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

The potential opportunities for improving energy efficiency and lower CO 2 emissions in raw material generation and production of concrete are smaller than in cement ...

Coal washing plant with Density separation, flotation is used for coal beneficiation, cleaning process to sepatate rock, ash, dirt in India, Indonesia.

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns.

View a 3D animated video of the cement production process to learn how cement is made by CEMEX.

Lucky Cement Limited (LCL) is one of the largest producers and leading exporters of quality cement in Pakistan, with a production capacity of million tons.

Cement microscopy. Cement microscopy is a very valuable technique, used for examining clinker, cement, raw materials, raw feed and coal. Every stage of the cement ...

Data From: TDF Content (% TDF compared to coal) Dioxins/Furans; 4 California Cement Kilns 6,1622: 20%: Increased between 53% and : 5 Canadian Cement .

japanese japanese clean technologies technologies for south african cement industry cement industry 6, september 2012

The term brick refers to small units of building material, often made from fired clay and secured with mortar, a bonding agent comprising of cement, sand, and ...

Dalmia Bharat, a conglomerate in India, has its presence in cement, sugar, refractories power manufacturing. The group companies happen to be among the fastest ...

How Cement is made at Continental. Cement is made from common materials such as limestone, clay, silica, and iron ore. Principle raw materials are a blend of 88% ...

Though "cement" and "concrete" are often used interchangeably, concrete is actually the final product made from cement. The primary component of cement is ...

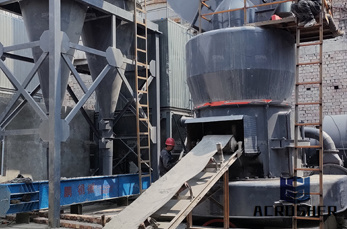

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Brochures within the Schenck Process Group . The brochures below can be downloaded directly. Just click on your selection. You also can order our ...

Know Daily Iron and Steel Price of Ms Scrap Rate In Indian Price and Old Machinery

Coalderived coke was the fuel used in most static kilns and so was the dominant fuel in the cement industry in the nineteenth century. Coal could not be used in ...

Loesche has provided a LM 56 3+3 CS vertical roller mill to Attock Cement Pakistan Ltd, for the grinding of cement clinker. The new mill will be used in the new line ...

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 4 WORLD BANK GROUP • Developing a staged combustion process .

Special Economic Zone at Villayat, District Bharuch, Gujarat Jubliant Infrastructure Limited

WhatsApp)

WhatsApp)